Industrial progress is rarely announced with spectacle. More often, it hums steadily in the background, carried forward by machines whose reliability is assumed and whose failure would be catastrophic. Lufkin Gears belong to that hidden category of essential technology. For more than a century, they have transferred power inside oilfields, power plants, mills, and factories—quietly converting motion into work, and force into productivity.

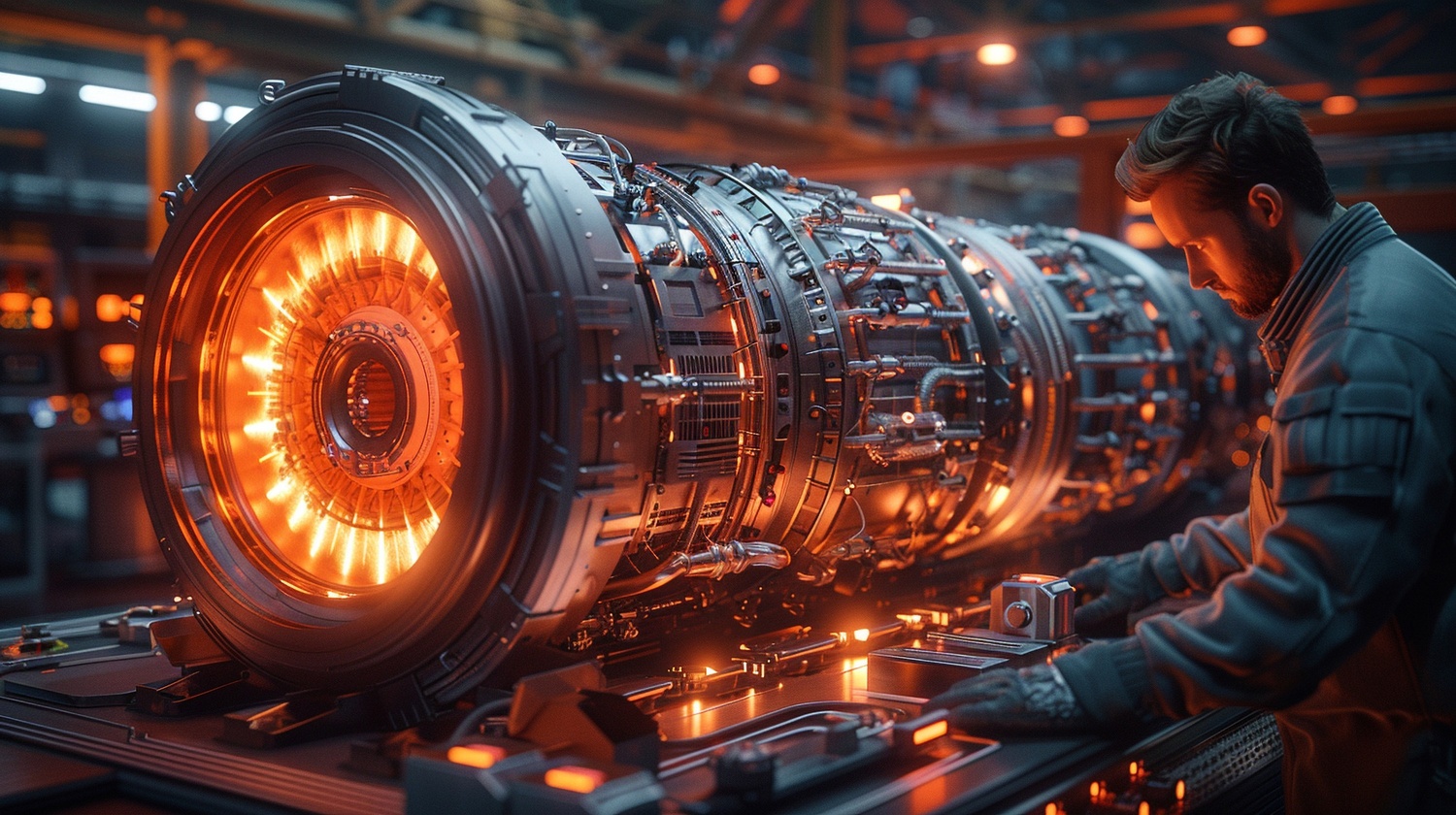

In the first moments of understanding Lufkin Gears, one encounters not a consumer brand but an industrial lineage. These are not gears meant to be admired; they are gears meant to endure. Designed for environments where downtime can cost millions and safety margins are unforgiving, Lufkin gear systems sit at the mechanical core of compressors, turbines, conveyors, and mills across the world.

What began as a regional machine shop in Lufkin, Texas, grew alongside America’s industrial expansion, adapting to wars, energy booms, globalization, and the modern demand for efficiency and precision. Over time, Lufkin became synonymous with custom-engineered gearboxes—large, complex systems built not for mass markets but for singular, mission-critical roles.

Today, under the Baker Hughes industrial portfolio, Lufkin Gears represent a convergence of old-world mechanical craftsmanship and modern engineering science. This article traces that evolution: how Lufkin Gears are designed, why they matter, and how they continue to shape heavy industry in ways most people never see—but depend on every day.

Origins in East Texas: Building Strength Before Scale

The story of Lufkin Gears begins in the early twentieth century, when industrial America was defined by railroads, sawmills, and the first waves of oil exploration. The Lufkin Foundry & Machine Company emerged in this environment, serving local industries that demanded rugged, repairable machinery rather than refined elegance.

Early success came from understanding stress—mechanical stress, material stress, and economic stress. Equipment had to work continuously, often far from supply chains or skilled labor. Failure was not theoretical; it was immediate and costly. This reality shaped the company’s approach to gearmaking long before “industrial standards” became formalized concepts.

As oil production expanded across Texas, Lufkin’s machinery found new purpose in pumping units and power transmission systems. The enclosed geared pumping unit marked a turning point, bringing improved efficiency, safety, and durability to oilfield operations. These early designs established the company’s reputation for engineering solutions that prioritized longevity over convenience.

World War II further accelerated Lufkin’s technical maturity. Manufacturing for military needs demanded tighter tolerances, higher volumes, and strict quality controls. When the war ended, those capabilities translated naturally into industrial gear production, positioning Lufkin for decades of postwar expansion.

What Makes a Lufkin Gear Different

At a basic level, a gear changes speed, torque, or direction. At an industrial level, a gear becomes a structural element of an entire system. Lufkin Gears are designed with that reality in mind.

Rather than standardized, off-the-shelf components, most Lufkin gearboxes are engineered-to-order. Each unit reflects the operating environment it will face: rotational speed, torque load, temperature variation, lubrication constraints, and expected service life. In many applications, these systems are expected to operate continuously for decades.

Low-speed gearboxes, for example, reduce high rotational input into slow, powerful output suitable for crushing, grinding, or conveying massive materials. High-speed parallel-shaft gearboxes perform the opposite task, transmitting turbine energy to compressors or generators with extraordinary precision and balance.

The design process integrates gear tooth geometry, shaft alignment, bearing selection, and housing rigidity into a single system. Every choice influences vibration, heat generation, efficiency, and long-term wear. The result is not just a gear set, but a mechanical ecosystem.

Materials, Machining, and Mechanical Discipline

Lufkin’s durability reputation rests heavily on materials science. Gear teeth are not merely cut; they are engineered through heat treatment processes that harden surfaces while preserving internal toughness. This balance allows teeth to resist surface wear without becoming brittle under load.

Precision grinding ensures that gear profiles mesh smoothly, reducing noise, vibration, and energy loss. Bearings—often fluid-film or advanced rolling-element designs—support immense loads while maintaining alignment under thermal expansion.

Equally important is housing design. Massive steel casings prevent distortion under load, preserving internal geometry even as torque levels fluctuate. Lubrication systems are integrated from the outset, ensuring consistent oil flow and thermal stability.

Before deployment, many gearboxes undergo full-load testing that simulates real operating conditions. This step transforms theoretical reliability into proven performance, ensuring the gearbox behaves predictably long before it reaches a customer’s site.

Global Manufacturing and Engineering Reach

Although rooted in Texas, Lufkin’s engineering presence expanded globally as industrial markets diversified. Facilities in Europe added specialized expertise in high-speed and epicyclic gear systems, while service hubs around the world provided localized support.

This global footprint is not simply logistical. Different regions bring different engineering traditions—reflected in design approaches, testing philosophies, and service practices. Together, they allow Lufkin Gears to serve industries that operate under varied regulatory frameworks and environmental conditions.

Crucially, global reach also supports long-term service. Industrial gearboxes often outlive the companies that install them. Lufkin’s ability to repair, upgrade, and remanufacture gear systems—sometimes decades after original installation—has become a defining advantage.

Where Lufkin Gears Do Their Work

Energy Production

In power generation, gearboxes bridge the mechanical mismatch between turbines and generators. Lufkin’s high-speed gear systems operate under extreme rotational forces, where imbalance or vibration can compromise entire plants. Their precision allows energy systems to operate smoothly, efficiently, and safely.

Oil and Gas Operations

From upstream pumping units to downstream processing facilities, gearboxes regulate motion in environments defined by heat, pressure, and isolation. Lufkin’s oilfield heritage remains visible in designs built to endure continuous operation with minimal intervention.

Heavy Manufacturing and Processing

Steel mills, cement plants, sugar mills, and mining operations rely on torque-heavy machinery. Here, gearboxes absorb shock loads, manage variable inputs, and keep production lines moving. In these settings, reliability is not a preference—it is an operational requirement.

Marine and Industrial Infrastructure

In marine propulsion and industrial infrastructure, space constraints and power density become critical. Compact yet powerful gear solutions allow large systems to function efficiently within limited footprints.

Service, Repair, and the Economics of Longevity

A defining aspect of Lufkin Gears is their service life—and the support systems built around it. Repair and remanufacturing are not afterthoughts; they are integral to the product philosophy.

Field engineers diagnose wear patterns, vibration signatures, and lubrication conditions to predict failures before they occur. Remanufacturing often incorporates modern materials and design improvements, extending the usefulness of existing assets rather than replacing them outright.

This approach aligns with modern industrial economics, where sustainability, cost control, and uptime are tightly linked. In many cases, upgrading an existing gearbox delivers better performance than installing an entirely new system.

Engineering Tradition in a Digital Age

While gearmaking is a mechanical discipline, modern Lufkin systems increasingly integrate digital monitoring. Sensors track temperature, vibration, and oil quality, feeding data into predictive maintenance systems that reduce unexpected failures.

Yet the digital layer does not replace mechanical discipline—it reinforces it. Data is only valuable when paired with designs that respond predictably to stress. Lufkin’s long engineering tradition provides the foundation that makes modern monitoring meaningful.

Conclusion

Lufkin Gears tell a story that mirrors industrial history itself: a progression from regional craftsmanship to global engineering, from mechanical intuition to data-informed precision. They are not symbols of innovation in the popular sense, but of continuity—proof that well-designed machines can outlast economic cycles, technological trends, and even generations of operators.

In a world increasingly defined by speed and disruption, Lufkin Gears represent something quieter and more enduring. They remind us that progress often depends not on novelty, but on reliability—the kind built slowly, tooth by tooth, over more than a century of work.

FAQs

What are Lufkin Gears primarily used for?

They are used in heavy industrial applications such as energy production, oil and gas processing, mining, cement manufacturing, and large-scale material handling.

Are Lufkin gearboxes custom-built?

Most Lufkin gear systems are engineered-to-order, designed specifically for each application’s load, speed, and environmental requirements.

How long do Lufkin Gears typically last?

With proper maintenance, many units operate for several decades, often undergoing refurbishment or upgrades rather than full replacement.

Can older Lufkin gearboxes be upgraded?

Yes. Repair and remanufacturing services often incorporate modern materials, bearings, and monitoring technologies.

Why are industrial gears so large compared to consumer gears?

Industrial gears handle extreme torque, continuous operation, and harsh environments, requiring heavier materials and more robust designs.