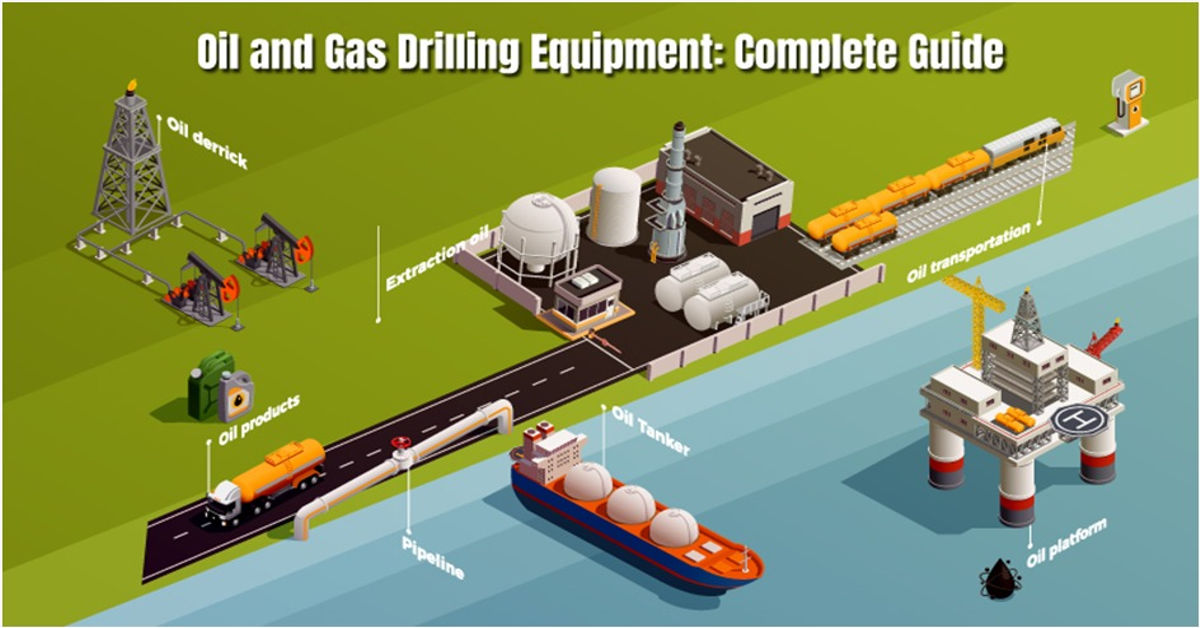

A job requires tools, machinery, and facilities, which are called equipment, enhancing productivity in minimal time. When it comes to the oil and gas industry, knowing the details of oil and gas drilling equipment used in drilling rigs is crucial for drilling and petroleum engineers. With adequate equipment, a well can be drilled effortlessly. This comprehensive guide will assist you in understanding the uses of each piece of equipment used in oil and gas drilling.

Whether you are a drilling engineer, geoscientist, or expert associated with the oil and gas industry, this informative piece will deliver more profound insights into drilling equipment utilized in a rig, making you knowledgeable.

Let’s first understand the drilling process and explore further.

What is Drilling, and What is an Oil and Gas Rig?

In the oil and gas industry, drilling is the foremost process, where a deep hole is drilled inside the earth’s core to bring hydrocarbons to the land. Oil and gas drilling in the US dates back to 1859, when Edwin Drake drilled the first successful oil well near Titusville, Pennsylvania, US. This well was 69 feet deeper and produced around 25 barrels of oil daily.

Currently, oil and gas drilling initiatives are shaping the landscape of energy firms, delivering magnificent economic benefits through employment opportunities and tax revenue at a global scale.

Drilling on a surface is carried out with the help of a large assembly called a rig. Rigs are huge structures built over wells to extract the minerals beneath the land, especially on offshore sites. These rigs comprise various equipment and tools, which are listed below.

List of Oil and Gas Drilling Equipment

| Drilling Equipment | Uses |

| Bell Nipple | Enables the drilling mud to flow back to the mud tanks and is installed on the top side of blowout preventers. |

| Blowout Preventer | It prevents gasses, fluids, and other liquids from unnaturally blowing out from the well bore and is fitted at the wellhead. |

| Casing Head | It helps bolt the surface equipment, like a Christmas tree for producing a well or a blowout preventer for drilling a well. It is a large metallic flange welded onto the upper side of the conductor pipe. |

| Centrifuge | Helps separate the sand and smaller silts from the drilling fluids and is fitted just above or on top of the mud tanks. |

| Crown Block | A stationary device with a set of pulleys helps lift heavier material even in weather conditions. |

| Degasser | It separates the gas, air, or both from the drilling fluids and is placed on the upper side of mud tanks. |

| Derrick | It raises and lowers the drill string out of and into the wellbore and acts as a supporting structure for the equipment. |

| Desilter or Desander | It comprises a set of hydrocyclones installed on top of mud tanks, which discretely remove fine silts and sand from the drilling fluids. |

| Drawworks | The mechanical part containing the spool reels in and reels out the drill line to minimize or raise the traveling block. |

| Drill Bits | Punctures the rock layers in the land to reach the mineral reserves. |

| Drill Floor | It is the plain surface of the rig containing various tools for making the pipeline connections of the drill pipe. |

| Drill Line | Raises and minimizes the drill string threaded through the crown and traveling blocks. |

| Drill Pipe | Attaches the surface equipment to the bottom hole assembly and acts as a conduit for drilling fluids in the surface. |

| Drill String | It is the assembly containing various tools, such as heavy-weight drill pipes, light-weight drill pipes, drill collars, and others, that run into the wellbore to facilitate well drilling. |

| Elevators | Helps raise and lower the pipes and other tools inside and out of drilling holes. |

| Flow Line | It is connected to the bell nipple and exceeds the shale shakers to smother the flow of drilling fluid back to the mud tanks. |

| Goose Neck | Supports weight easily and delivers a downward angle for the Kelly hose to hang from. |

| Kelly Drive | It is a hexagonal, octagonal, or square-shaped tubing that is installed through and is a crucial part of the rotary table that moves freely in a vertical direction while the rotary table turns it. |

| Kelly Hose | It attaches the standpipe to the kelly and enables free vertical movement of the kelly while facilitating the flow of drilling fluids down the drill string and through the system. |

| Racking Board | It is the walkway along the side of the derrick where human perform their tasks while tripping pipes. |

| Mud Motor | Rotate the drill bit independently from the remaining drill string and is installed just the upper side of the drill bit. |

| Mud Pump | Helps flow the drilling fluids through the system easily. |

| Mud Tank | Stores the drilling fluids until they are required down the wellbore. |

| Setback | Protects the end part of the drill pipe and is the part of the drill floor. |

| Rotary Table | Spins the drill string in a clockwise direction to precisely drill a borehole on the surface. |

| Shale Shaker | Divides the drilling fluids from drill cutting prior to it being pumped back down to the wellbore. |

| Stand | It contains two or more joints of drill pipe attached and stood in a vertical direction in the derrick, generally during tripping pipe. |

| Stand Pipe | Delivers the essential head pressure required to attain adequate drilling fluid circulation and is placed along the derrick in a vertical direction. |

| Suction Line | Takes out the drilling fluids from the mud tanks. |

| Swivel | Enables the easier spinning of the drill string without twisting the block. |

| Traveling Block | The combination of pulleys lowers and lifts the heavy objects and elements into and out of the wellbore. |

| Vibrating Hose | Attaches the mud pump to the standpipe to circulate the high pressure drilling fluids. |

In summary, mastering even the tiny intricacies of oil and gas drilling equipment can optimize operations to ensure success in this complex landscape. Let this knowledge be your strategic advantage.

We have covered the detailed functions and uses of all the necessary equipment used for oil and gas drilling. From a small drilling bit to a large rig assembly, every oil and gas drilling equipment puts their efforts into drilling a successful well for easier mineral extraction, delivering significant profits through production.